Which Pvc Cement To Use

How to Glue and Join PVC Plastic Piping

The secrets to fast, leak-proof connections

![]() Time

Time

Multiple Days

![]() Complexity

Complexity

Intermediate

![]() Price

Price

Varies

Introduction

How to brand leak-proof connections fast, whether you're using PVC, ABS or CPVC. Plus, common mistakes to avoid and how to fix them.

Tools Required

Materials Required

- Cement and primer

- Plastic pipage and fittings

- Transition coupling

Video: How to Glue PVC Pipes

Gary Wentz, an editor for Family Handyman, will show y'all how to gum PVC pipes to get a fast, leak-free seal.

Projection step-by-step (vii)

Make Square Cuts for Strong PVC Joints

- Make an improvised guide by screwing together scraps of 2x4.

- Saw using a handsaw with a blade that's iii or four inches wide.

- Note: Square pipe ends fit snugly into the fittings, assuasive plenty of contact area for the solvent cement to piece of work. They too make a smoother interior surface for improve water flow.

- Pro tip:Special saws for cut plastic pipe are a worthwhile investment if you do much plumbing work. You'll find them in the plumbing tool expanse or with the handsaws in near abode centers and hardware stores. Otherwise, whatever fine tooth saw volition work.

Pace 2

De-Burr the Inside

- Roll a quarter canvass of lxxx-dust sandpaper into a tube and flatten information technology slightly to match the curve of the pipe.

- File off the inner burrs with the sandpaper.

- Agree the sandpaper at an angle and sand the inside and exterior (see beneath) of the plastic pipe until you create slightly beveled edges.

- Note: Left in identify, burrs can snag hair and other droppings, causing clogs.

- Pro tip: You can remove burrs with a file or knife, merely sandpaper is easier to use and works cracking.

Step iii

De-Burr the Exterior

- Knock off the outer burrs with sandpaper.

- Notation: The pipe volition slip into the plumbing fixtures easier and you'll get a tighter fit.

Pace 4

Marker the Pipe and Fitting

- Dry-fit the pipe and PVC pipe connectors fitting, using a torpedo level if needed to align the fitting.

- Make a mark beyond the plumbing fixtures and pipe.

- Pro tip: By the time you spread the solvent cement on both the pipe and the fitting and press them together, you have only several seconds to get the alignment right before the pieces are stuck together. That's why it's a skilful thought to make alignment marks beforehand on PVC joints where orientation is disquisitional.

Step 5

Utilise the PVC Cement

- Wipe the inside of the fitting and the outside of the pipe with PVC primer.

- Allow it dry for about 10 seconds.

- Spread an even layer of solvent PVC cement on the inside of the fitting and outside of the pipe.

- Pro tip: To keep backlog solvent cement from being pushed into h2o piping, don't use also much to the within of the socket on the plumbing fixtures.

- Note: But swiping the piping with cement and pushing on the fitting won't ensure a strong joint. Yous want to make sure y'all have an even layer of cement over all mating surfaces.

Footstep 6

Push and Twist

- Marshal the plumbing equipment and pipage well-nigh a quarter turn from their final orientation.

- Button the pipage into the PVC pipe connectors fitting and twist the plumbing equipment until the marks are aligned.

- Pro tip: Twisting the plumbing equipment helps spread the solvent cement evenly to ensure a solid joint.

- Printing and concur the pipe for about xv seconds.

- Pro tip: If you let become immediately, the pipe may button out of the plumbing fixtures, resulting in a weak joint.

CAUTION!

The solvent vapors from the PVC primer and cement can brand you dizzy and are dangerous to your wellness. Make sure yous have plenty of ventilation or wear an approved organic vapor respirator when working with PVC primer and solvent cement.

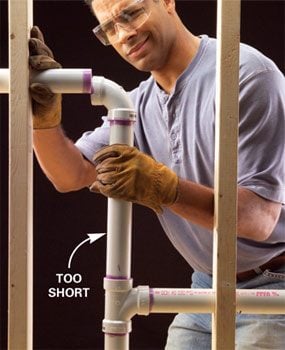

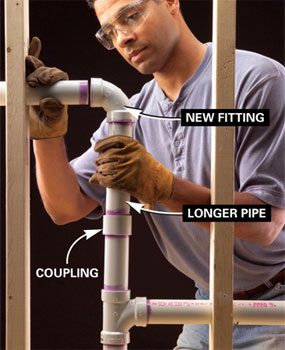

Ready Mistakes with a Coupling

-

- Note: Mistakes happen. Sometimes assembled PVC pipes don't reach the predrilled hole because we dry-fit the PVC pipes and forgot to allow actress length for "shrinkage."

- Saw out the bad department.

- Use a coupling to rejoin the parts, using new parts if necessary.

- Prime number (if needed) and cement the parts together.

- Pro tip: Buy extra fittings. Having extras on manus volition save a trip to the shop. And you can return the extras when yous're washed.

Step seven

Bring together Different Types of Pipage with Transition Coupling

-

- Note: Transition couplings have a flexible rubber sleeve surrounded past a metallic sleeve and band clamps. They're handy for connecting plastic pipe to bandage iron, copper or steel, specially if yous can't thread on an adapter. Each coupling is labeled with all the different types and sizes of pipes it can join.

- Slide the pipe ends into the transition plumbing fixtures.

- Turn the screws clockwise with a nut commuter to tighten the bands and seal the joint.

Apply the Proper Solvent for Each Type of Plastic

-

- Note:In that location are three common types of plastic plumbing pipe: PVC, CPVC and ABS. For a reliable seal, yous accept to use the solvent that's formulated for the pipe. All of them incorporate aggressive solvents and adhesives, so beware of drips and spills.

- White or beige pipes (PVC and CPVC) likewise crave a primer.

- You don't need a PVC primer with blackness ABS piping.

- Read the label to lucifer the solvent cement to the type of pipage you're using. Avert universal solvent cements.

Originally Published: November 02, 2020

Which Pvc Cement To Use,

Source: https://www.familyhandyman.com/project/how-to-glue-and-join-pvc-plastic-pipe/

Posted by: hiltnore1993.blogspot.com

0 Response to "Which Pvc Cement To Use"

Post a Comment